MANUFACTURING

Advanced Robot Machine

Robot Machine comtrol the processing tolerance more accuratly.

Advanced Robot Machine

Robot Machine comtrol the processing tolerance more accuratly.

Advanced Robot Machine

Robot Machine comtrol the processing tolerance more accuratly.

Advanced Robot Machine

Robot Machine comtrol the processing tolerance more accuratly.

Our Capacity

Our manufacturers are equipped with a complete line of advanced machines, such as Auto Robot Producing line, Robot welding machines, CNC Lathes, CMM machines, Auto Power coating line, Hydraulic Pressure Testing machine, robot control inspecting machines, etc. We have professional technical team group in designing and producing which can meet the customers different demand for hydraulic solution.

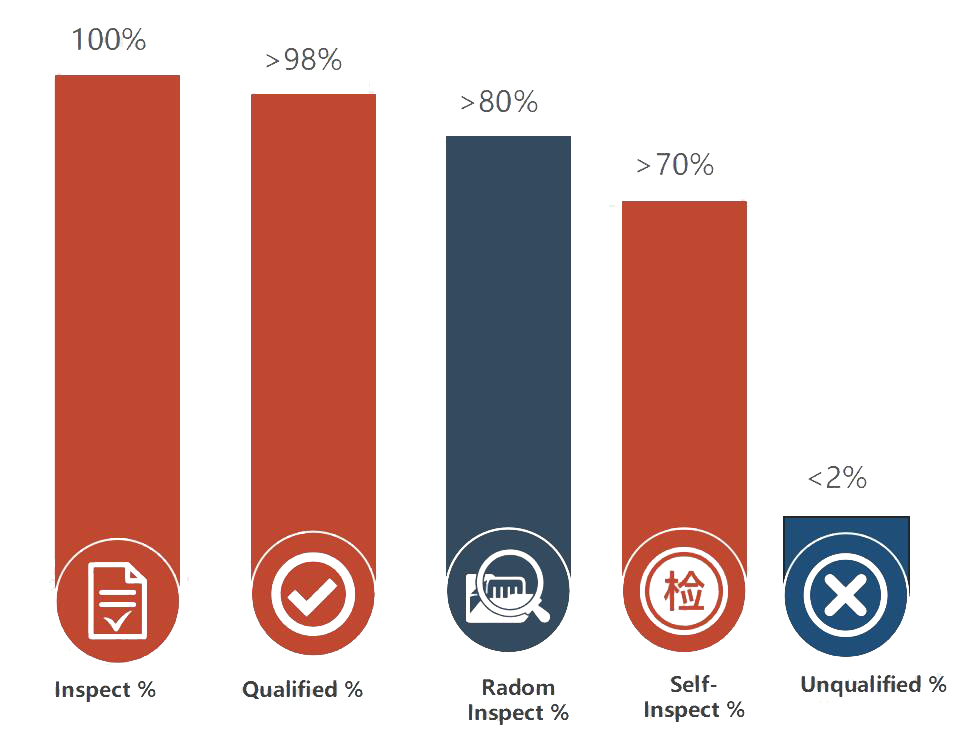

The to-be-delivered products are 100% tested.We focus on quality improvement, process effective management, flexibility and customer services, involvement and motivation of the entire company staff. The aim is to reach ZERO waste, defects, inventory and breakdowns by involving everyone in the company, spreading and standardizing achieved results.

Manufacturers are required to be qualified with ISO9001 standard, AWS D1.1, CNAS, IAF Certification, etc.

QUALITY

AXON regards quality as our core value. The quality control system starts from choosing raw material to having completed supervision by AXON's quality control department.

TEAM

AXON Team are working hard to improve products′ quality step by step according to the customers′ feedback and market requirement.

QUALITY CONTROL

AXON regards quality as our core value. The quality control system starts from choosing raw material to having completed supervision by AXON's quality control department. AXON Team are working hard to improve products′ quality step by step according to the customers′ feedback and market requirement.

Inspectin Process

Quality Standard

Handling of Nonconforming Product

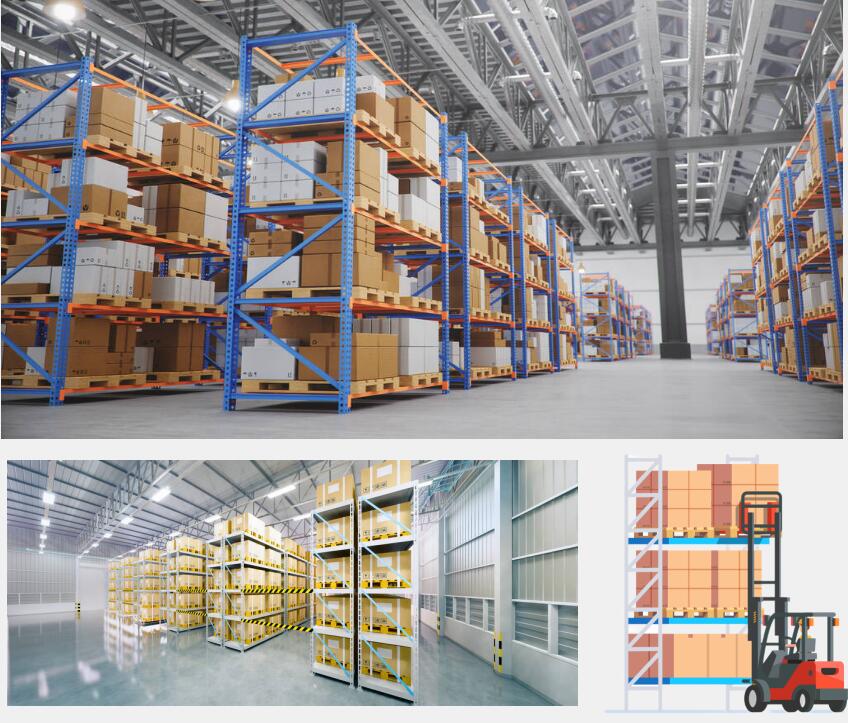

MANAGEMENT

Superior management system with ERP, MRP, APS. MES. MDC, benetifs for AXON professional management to support customers orders .

Our Capacity

Our manufacturers are equipped with a complete line of advanced machines, such as Auto Robot Producing line, Robot welding machines, CNC Lathes, CMM machines, Auto Power coating line, Hydraulic Pressure Testing machine, robot control inspecting machines, etc. We have professional technical team group in designing and producing which can meet the customers different demand for hydraulic solution.

The to-be-delivered products are 100% tested.We focus on quality improvement, process effective management, flexibility and customer services, involvement and motivation of the entire company staff. The aim is to reach ZERO waste, defects, inventory and breakdowns by involving everyone in the company, spreading and standardizing achieved results.

Manufacturers are required to be qualified with ISO9001 standard, AWS D1.1, CNAS, IAF Certification, etc.

EN

EN